- Original Designs

- Zero-Dead-Volume Valve

Zero-Dead-Volume Valve

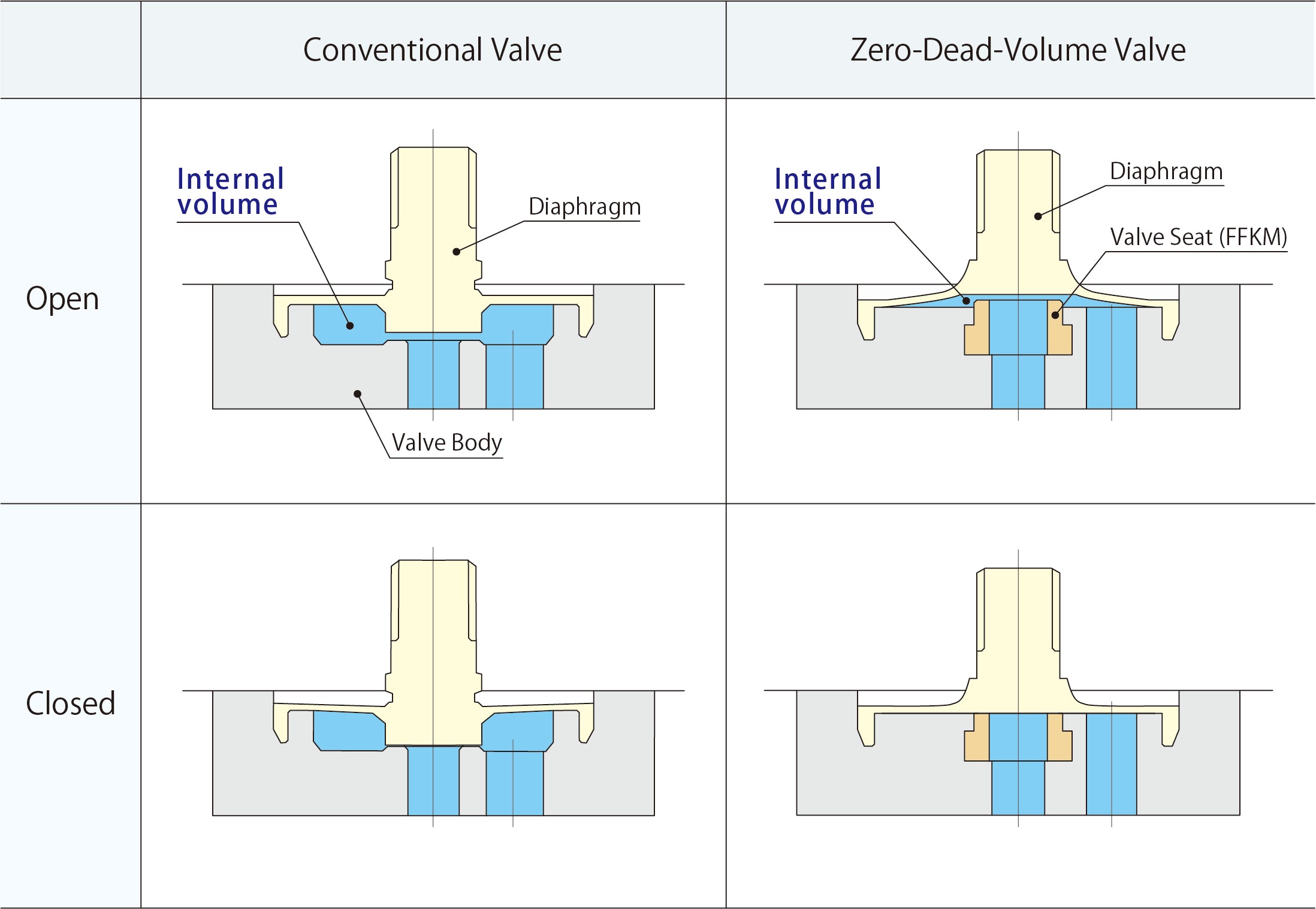

The "Internal-Volume" is the space between the diaphragm and the body. When the valve closes, this volume is trapped, often reducing the sensitivity of a test instrument. The protruding valve seat is hard in the old design and prevents the Teflon™ diaphragm from flattening against the valve body.

We use a uniquely soft, inert elastomer (FFKM) for the valve seat in the Zero-Dead-Volume system. When the valve closes, the soft protrusion presses flat, eliminating the internal volume.

Note: Details such as specifications, etc., may be changed without notice.

Features of the Zero-Dead-Volume

- Cross-contamination prevention.

- Faster flushing.

- Perfect ejection of air-bubbles.

- Reduction of sample or reagent volumes.

- The use of soft elastic valve seats also prevents particle induced leakage.

Influence of the Internal-Volume upon Accurate Analysis

- Due to the elastic properties of Perfluoroelastomer a slight decrease in flow rate has been observed after long periods of energization.

Models Incorporating the Zero-Dead-Volume Diaphragm

Comparative Data Table

| Model | Type | Internal Volume* |

| MTV-2-M6 | Conventional | 87 μL |

| MTV-2-M6N | Zero-Dead-Volume | 34 μL |

Note: *Passage volumes only.

If you are looking for Zero-Dead-Volume valves, our team of experts will gladly be of help to offer you the best models, including customized valves to meet your requirements. Please feel free to contact us with your questions and inquiries.