Custom Manifolds

We not only provide our customers with components such as valves, pumps etc., but also design and manufacture Custom Manifolds to satisfy our customers' requirements. These manifolds contribute to decrease in plumbing and minimization of the internal volume. Depending on the manufacturing technologies a manifold with channels of the minimum width as narrow as 0.2 mm is also possible to provide.

Characteristics of Custom Manifolds

Chemical Compatibility

Suitable, highly chemically inert materials such as PEEK, PPS, PTFE, etc can be chosen for the manifold.

Channel Configuration

Flow channel configurations with a common inlet or a common outlet, and a radial type or a line type are available according to your requirements. Through the use of a bonding technique, 3D flow channel configurations that cannot be produced by machining process are possible.

Number of Mounted Valves

The number of mounted valves can be selected. We have the experience of manufacturing a manifold unit with 192 valves.

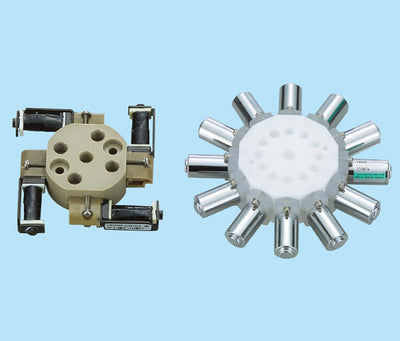

Examples of Custom Manifolds

|

Built-in TypeThe valve mechanism is built into the manifold to make a single integrated unit. 【Advantages】

【Disadvantages】

|

|

Valve Mounted TypeMultiple valves are mounted on a manifold in which only the channels are machined. Gaskets (mainly elastomers) are used for the channel connection parts. (Advantages) Mounted valves can be replaced for repair. Suitable for a manifold unit using lots of valves. The photo is an example of a manifold mounted with 196 valves. 【Advantages】

【Disadvantages】

|

|

In-line TypeBy directly connecting each port of multiple valves in line, a flow channel is produced. A manifold block is not used. 【Advantages】

【Disadvantages】

|