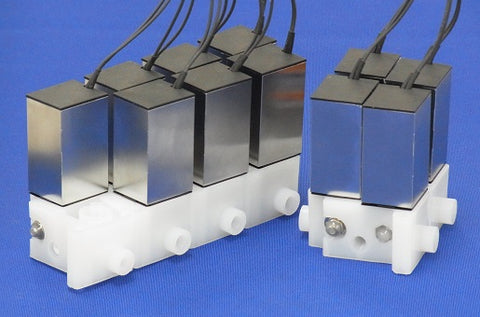

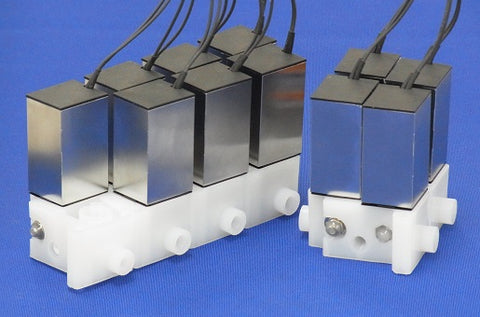

Flexible Joinable Stations

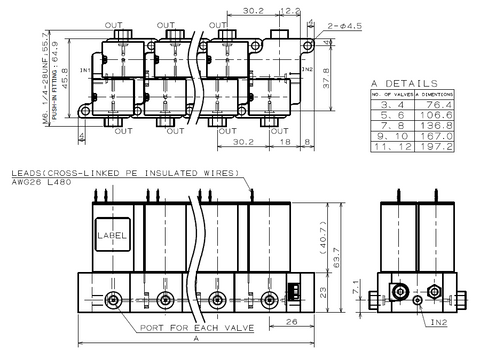

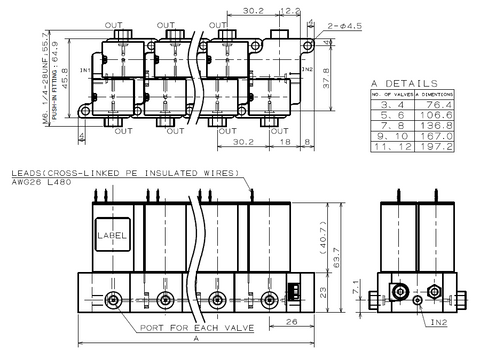

- Each basic block holds a pair of 2-way valves. Up to 6 blocks can be flexibly joined together to give a maximum of 12 stations. This manifold provides both a cost reduction and a flexible configuration that cannot be achieved by conventional molded manifolds.

- A 2-row construction enables a shorter length of manifold and a common channel, which contributes to a small internal volume and easy arrangement on an instrument.

- The extremely inert material ETFE (fluorocarbon polymer) is used for the block.

- A choice of diaphragm material is available: PTFE for the highest chemical compatibility or FKM/EPDM for cost-saving.

- In addition to M6 and 1/4-28UNF threads, the special option of the Push-in Fitting is also available for the port connection, which allows quick connection by just inserting the tubing.

Please feel free to contact us for more information about this molded manifold valve, the XTA-2E series.

Note: Details such as specifications, etc. may change without notice.

CONFIGURABLE FLOW SCHEMATICS

<1 x IN Port>

*IN Port location can be selected from the right or left side when the number of stations is odd. |

<2 x IN Ports> |

<3 x IN Ports>

*Only applicable when the number of stations is odd. |

|

|

|

Note: Details such as specifications, etc. may change without notice.

SPECIFICATIONS

Swipe left to see the remaining contents

| Model Number |

XTA-2E

|

| Method |

Solenoid Diaphragm Isolation Valve

|

| Type |

2-way NC (Normally Closed)

|

| Port Connection |

M6, 1/4-28UNF, or Push-In Fitting* (Option)

|

| Orifice(mm) |

1.6 mm

|

| Ambient Temperature Range |

5~50°C

|

| Rated Voltage |

12 or 24 VDC

|

| Power Consumption |

2.8 W multiplied by the number of valves

|

| Operating Pressure |

IN: -90 to 200 kPa

OUT: 0 to 50 kPa

|

| Other Wetted Materials |

PTFE Diaphragm Model: ETFE, PTFE, and FFKM

Elastomer Diaphragm Model: ETFE and FKM (Optionally EPDM)

|

| Notes |

| Number of Valves |

Option to have 3 to 12 Valves |

| Duty Cycle |

Continuous |

Note: Details such as specifications, etc. may be changed without notice.

*: The Push-In Fitting uses PPS for the body material and uses FKM as the inside sealing material.

|